简介:Introduction

工作原理:Working principle

| 项目 | 旋压式脱水机 | 板框式压滤机 | 带式压滤机 | 叠螺机 | 离心机 |

| 集成度 | 高 | 低 | 较低 | 较低 | 高 |

| 密闭性 | 最好 | 最差 | 差 | 差 | 一般 |

| 能耗 | 低 | 较高 | 一般 | 较低 | 很高 |

| 脱水率 | 较干 | 干 | 湿 | 一般 | 一般 |

| 维护性 | 好 | 差 | 较差 | 较好 | 较差 |

| 噪声 | 无 | 较低 | 较低 | 较低 | 高 |

| 拓展性 | 易 | 较难 | 难 | 较易 | 难 |

| 开停机 | 易 | 难 | 较难 | 较易 | 较难 |

| 人机环境 | 好 | 差 | 较差 | 较差 | 差 |

| 冲洗水 | 较少 | 多 | 较多 | 较多 | 少 |

| Item | Rotary press filter | Plate and frame filter | Belt filter | Stacking screw machine | Centrifuge |

| Integration | high | low | lower | lower | high |

|

Hermetic property |

best |

least |

poor | poor | general |

| Energy consumption | low | higher | average | lower | high |

|

Dehydration rate |

drier | dry | wet | average | average |

| Maintenance | good | poor | poorer | better | poorer |

| Noise | no | low | low | low | high |

| Expandability | easy | harder | hard | easier | hard |

| Start and scenter | easy | hard | harder | easier | harder |

| Man-machine environment | good | poor | poorer | poorer | poor |

| Flushing Water | less | much | more | more | little |

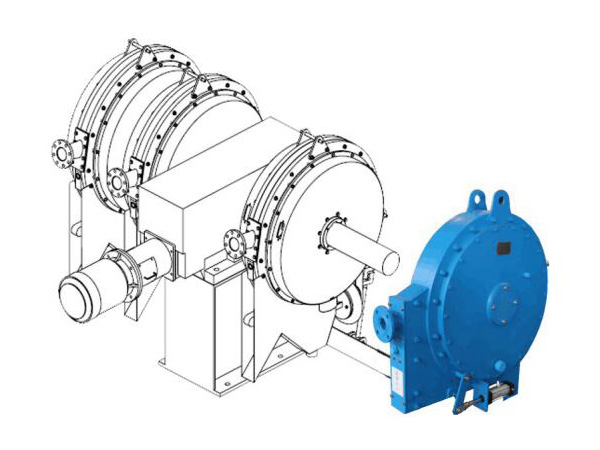

Comparison between Rotary press filter and Centrifuge

|

|

旋转挤压脱水机 |

离心脱水机 |

|

驱动系统 |

简单,单转子 |

复杂,双转子系统 |

|

转速 |

低速转0.5-3.5rpm |

高转速1500-3500rpm |

|

能耗 |

低能耗:安装功率低,能耗低。 |

高能耗:安装功率大,能耗高。每吨滤渣耗能170kW,其他能耗也不可忽视 |

|

开停机 |

开停机过程简单,短暂;可以经常性开停机 |

复杂,持续时间长;停机后转鼓还能转动一段时间;不可能经常性开停机 |

|

维修 |

在污水处理厂用常规工具即可维修 |

需要运送到制造厂由专业的机械师专门的维修 |

|

不完全操作 |

对于多通道的机型,部分单元的移除或暂停使用不影响其他单元正常运行 |

整改机器同时处于运行状态或停机状态 |

|

振动分析 |

无振动,不需要做振动分析或预防保养 |

振动分析和预防保养很重要,需要对相关人员做专门的培训 |

|

絮凝 |

包括外带可变速搅拌装置的絮凝器,可优化絮凝,减少聚合物的浪费 |

絮凝发生在离心机内部,不易控制,聚合物利用率低消耗量大,增加经费 |

|

可靠性 |

零部件少,低转速和简单设计保证高可靠性 |

零部件多,高转速,功率高,可靠性低 |

|

捕获率 |

高(固相回收率>95%) |

低,若无人看管会更低 |

|

沙砾影响 |

大通道、低速运动,沙砾影响小 |

污泥中的沙砾会造成离心机严重磨损 |

|

长纤维影响 |

大通道、低速运动,可适用于含长纤维状物体污泥 |

高速旋转长纤维状易堵塞在离心机内部 |

|

滤渣干燥度 |

可以得到非常干的滤渣,对进料含水率要求范围广,出料含水率可调 |

对进料含水率要求苛刻,出料不可能可到同等干燥度的滤渣 |

|

润滑系统 |

不需要外部润滑系统 |

通常需要外部润滑系统 |

|

维护费用 |

低 |

高 |

|

其他 |

无需对进料进行破碎处理 |

需要对进料破碎处理 |

| Rotary press filter | Centrifuge | |

| Drive System | Simple, single rotor system | Complex, dual rotor system |

| Rotating speed | Low speed to 0.5-3.5rpm No special requirements | High speed 1500-3500rpm It is necessary to consider the load of the machine on the building, control the noise, and monitor the vibration and temperature of the motor, drum, and spiral |

| Energy consumption | Low energy consumption: Low installation power and low energy consumption. 10kW/ton of filter residue | High energy consumption: large installation power and high energy consumption.The energy consumption offilter residue is 170kW/ton,and otherenergy consumption cannot be ignored |

| Start and stop | The start and stop process is simple and short; it can be started and stopped frequently | Complex and long duration; the drum can still rotate for a period of time after shutdown; it is impossible to start the shutdown frequently |

| Maintenance | Can be repaired with conventional tools in sewage treatment plants | Need to be transported to the manufacturing plant for specialized repair by a professional mechanic |

| Incomplete operation | For multi-channel models, the removal or suspension of someunits does not affect the normal operation of other units | Rectifying the machine needs to be in the running state or stop state at the same time. |

| Vibration analysis | No vibration, no need for vibration analysis or preventive maintenance | Vibration analysis and preventive maintenance are very important, and relevant personnel need to be specially trained. |

| Flocculation | The flocculator includes a variable speed agitator to optimize flocculation and reduce polymer waste. | Flocculation occurs inside the centrifuge, it is not easy to control, the polymer utilization rate is low, the consumption is large, and the cost is increased. |

| Reliability | Fewer parts, low speed and simple design ensure high reliability | Many parts, high speed, high power, low reliability |

| Capture rate | High (solid phase recovery rate> 95%) | Low, lower if left unattended |

| Impact of gravel | Large channel, low speed movement, small impact of gravel. | The gravel in the sludge can cause serious wear on the centrifuge. |

| Long fiber effect | Large channel, low speed movement,suitable for sludge containing long fiber | High-speed rotating long fiber shape is easy to block inside the centrifuge. |

| Filter residue dryness | Can get very dry filter residue, a wide range of requirements for feed moisture content, adjustable outlet moisture content | Strict requirements on the moisture content of the feed, it is impossible to get the filter residue with the same dryness in thedischarge |

| Lubrication system | No external lubrication system required | Usually requires an external lubrication system |

| Maintenance costs | low | high |

| Others | No need to crush the feed | Need to crush the feed |

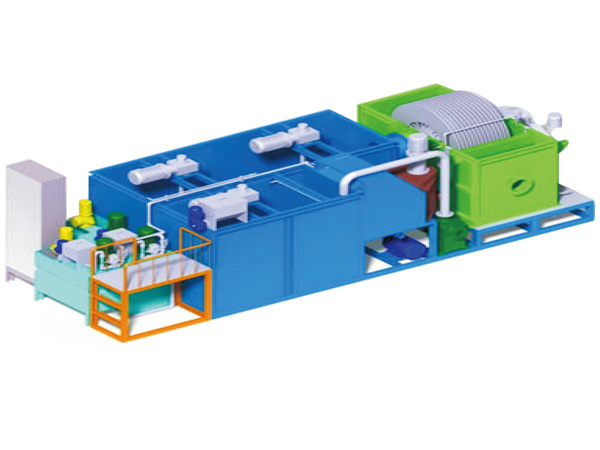

设备组合:Equipment combination

|

参数 |

处理能力(m3/h) |

泥饼含固率(%) |

主机转速(r/min) |

电机功率 |

主机重量 |

外形尺寸 |

|

YJ600-2L |

4-12 |

60—80% |

1-3 |

2.2 |

2 |

1.4×1.6×1.2 |

|

YJ900-2L |

8-20 |

60—80% |

1-3 |

3.0 |

4.6 |

1.6×1.8×1.5 |

|

YJ1200-2L |

20-40 |

60—80% |

1-3 |

4.0 |

7.5 |

1.8×2.1×1.8 |

脱水流程:Dehydration process